TAP INTO OVER 130 YEARS OF ENGINEERING EXPERTISE

Learn everything it takes to keep your mission-critical equipment running reliably.

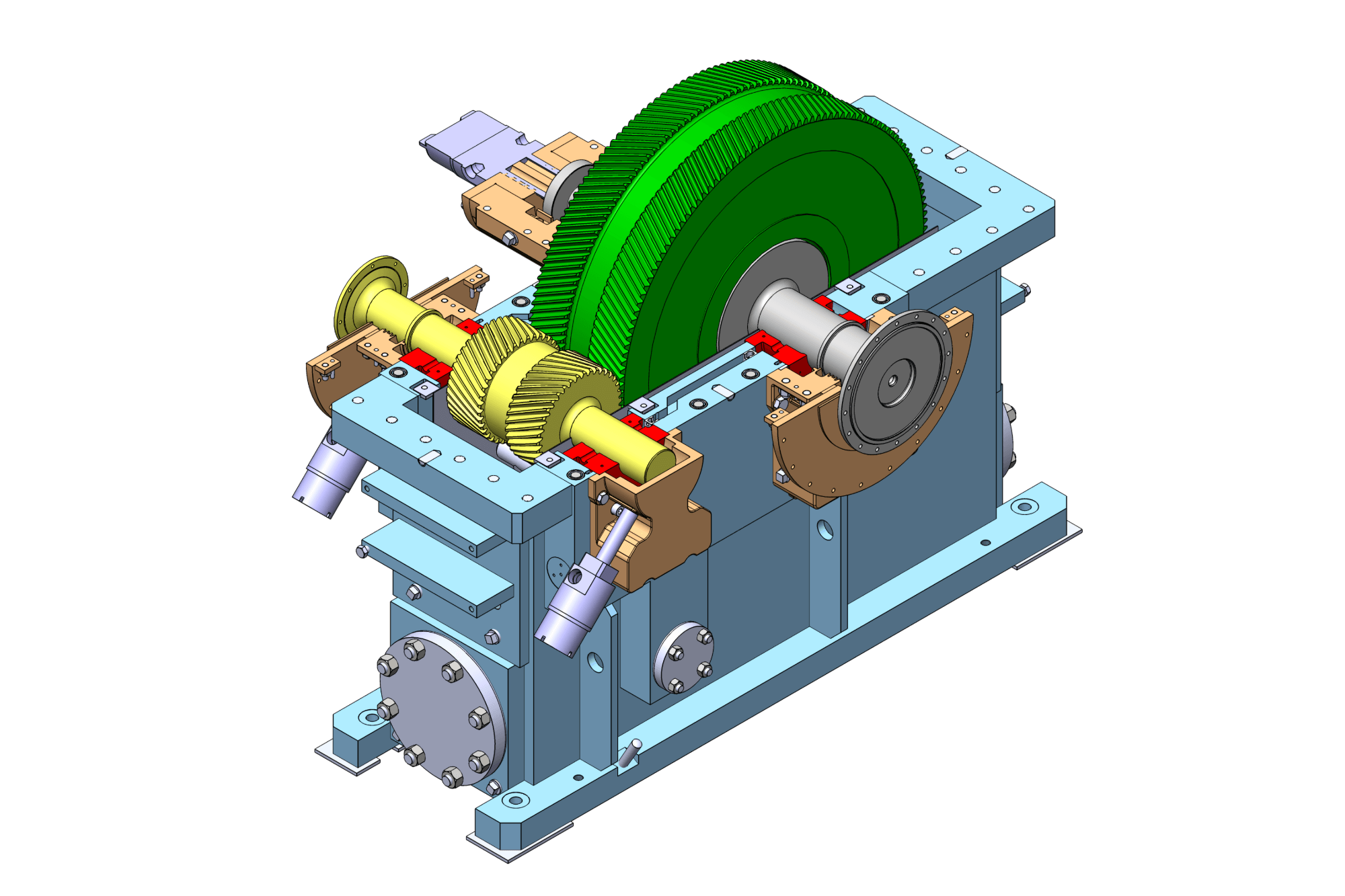

An industry leader in in power transmission and gearing solutions since 1892, Philadelphia Gear® has compiled a deep library of training resources, whitepapers, configuration tools, and more.

Browse our Knowledge Center to find your solution today.

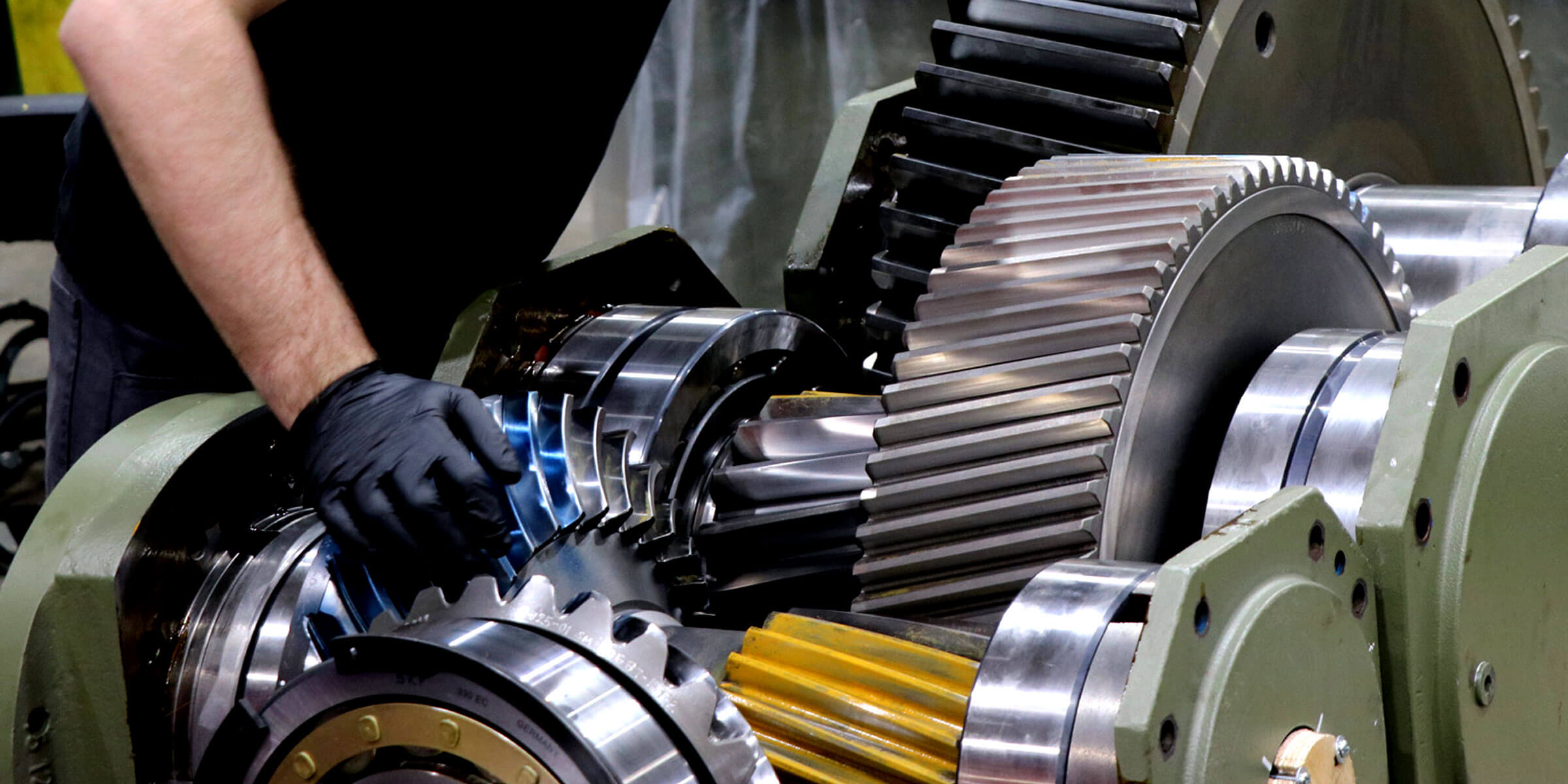

LEARN GEAR FUNDAMENTALS IN FOUR HOURS

Get your maintenance and operations teams trained with Gear 101: An Introduction to Gearing Concepts and Elemental Gearbox Operation.

Philadelphia Gear’s four-hour program provides a concise yet comprehensive overview of complex rotating equipment – and their foundational operating principles – that keep plants running smoothly.

Learn more

Brochures

Whitepapers

Case Studies

Videos

Gear related videos

Mark 8 Controller

Proper Gearbox Safety Procedures

Gearbox Backlash Check

Learn About Philadelphia Gear Right-angle Pump Drive Feature

Gearbox Lubrication Components

Checking Gear Tooth Contact

Performing Magnetic Particle Inspection - Part 2

Dye Penetrant Check - Part 1

Dye Penetrant Check - Part 2

Performing Magnetic Particle Inspection - Part 1

Gear Hobbing Basics

Gearbox Overspeed Trip Mechanism

Intro to Cooling Tower Drives

Timken Power Systems industrial drivetrain repair services

Tour Standard Machine’s 175,000 Sq. Ft. Facility

Mark 8 Controller T

Engineering Custom Pump Drives to Preserve the Everglades

Motor related videos

Spinning Random Wound Electric Motor Coils

Restacking an Electric Motor Core

AC Motor Coil Manufacturing

Babbitt Bearing Repair

DC Motor Coil Manufacturing

Wind Turbine Wye Ring Basics and Tech Tips

H and N Wind and Electric Service Capabilities

Vacuum Pressure Impregnation (VPI) Process

Large Industrial Motor and Generator Repair Experts

Rotor Removal on Large Generator

Motor and Generator Test Stand Lubrication System

Smith Services' Babbitt Bearing Repair Center

Blower 3 Startup

Motor Dynamic Balancing

On-site Oil Change - 1500 HP Motor

Motor Test Run

Electric Motor Repair Tips on Changing Bearing Types

Configuration Tools

-

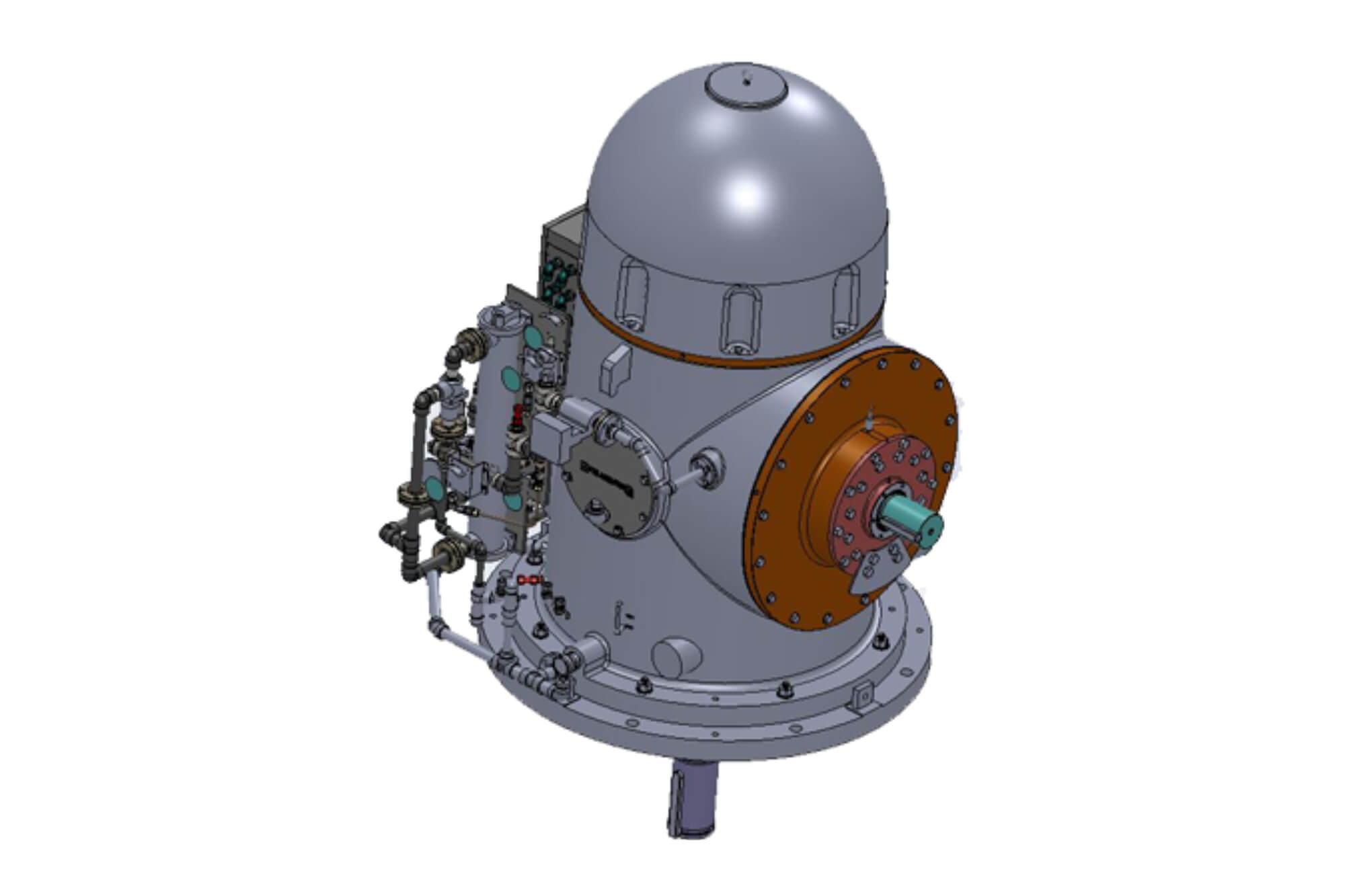

Cooling tower gearboxes

-

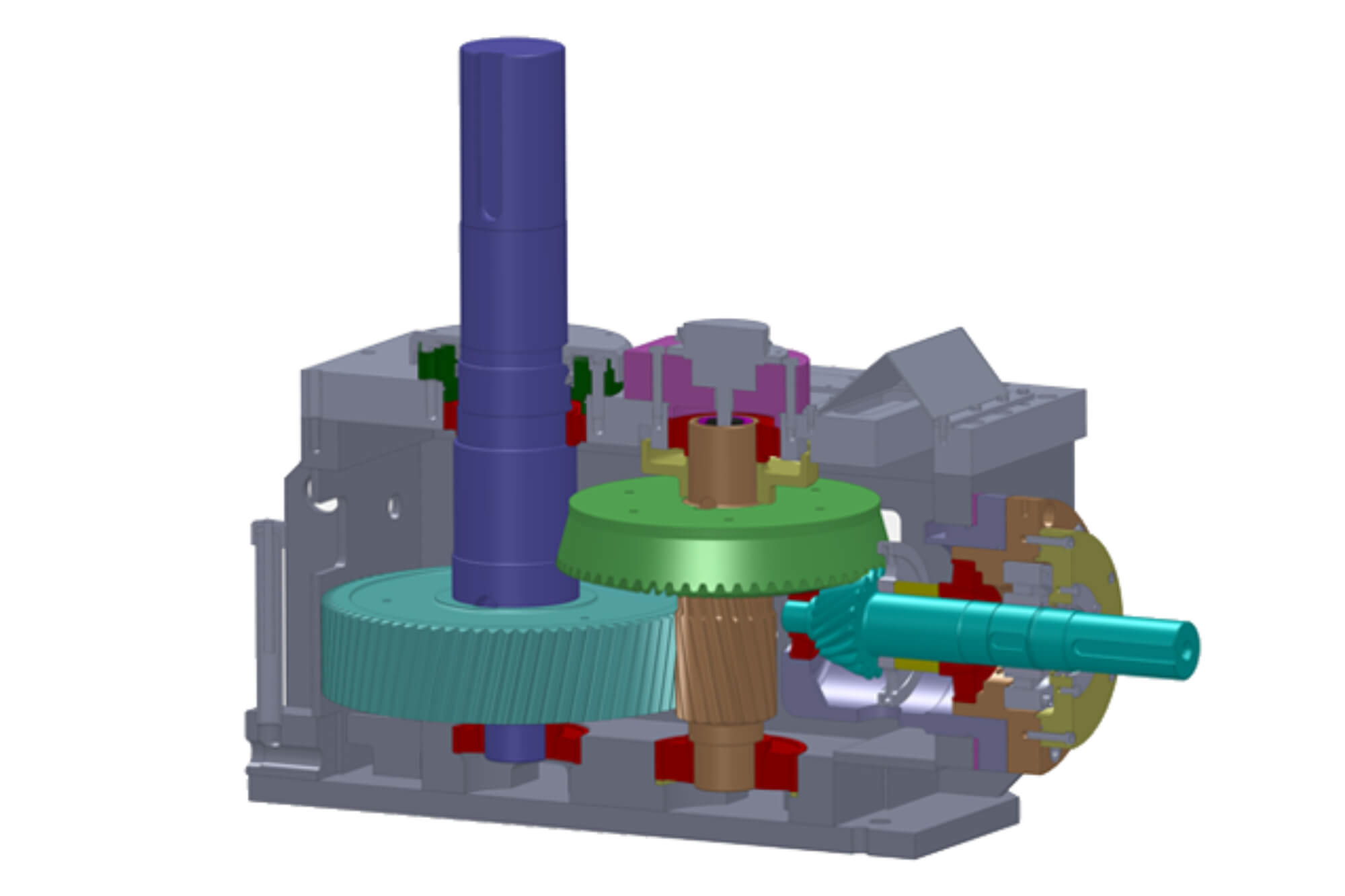

Pump Gearboxes

-

High-speed gearboxes

-

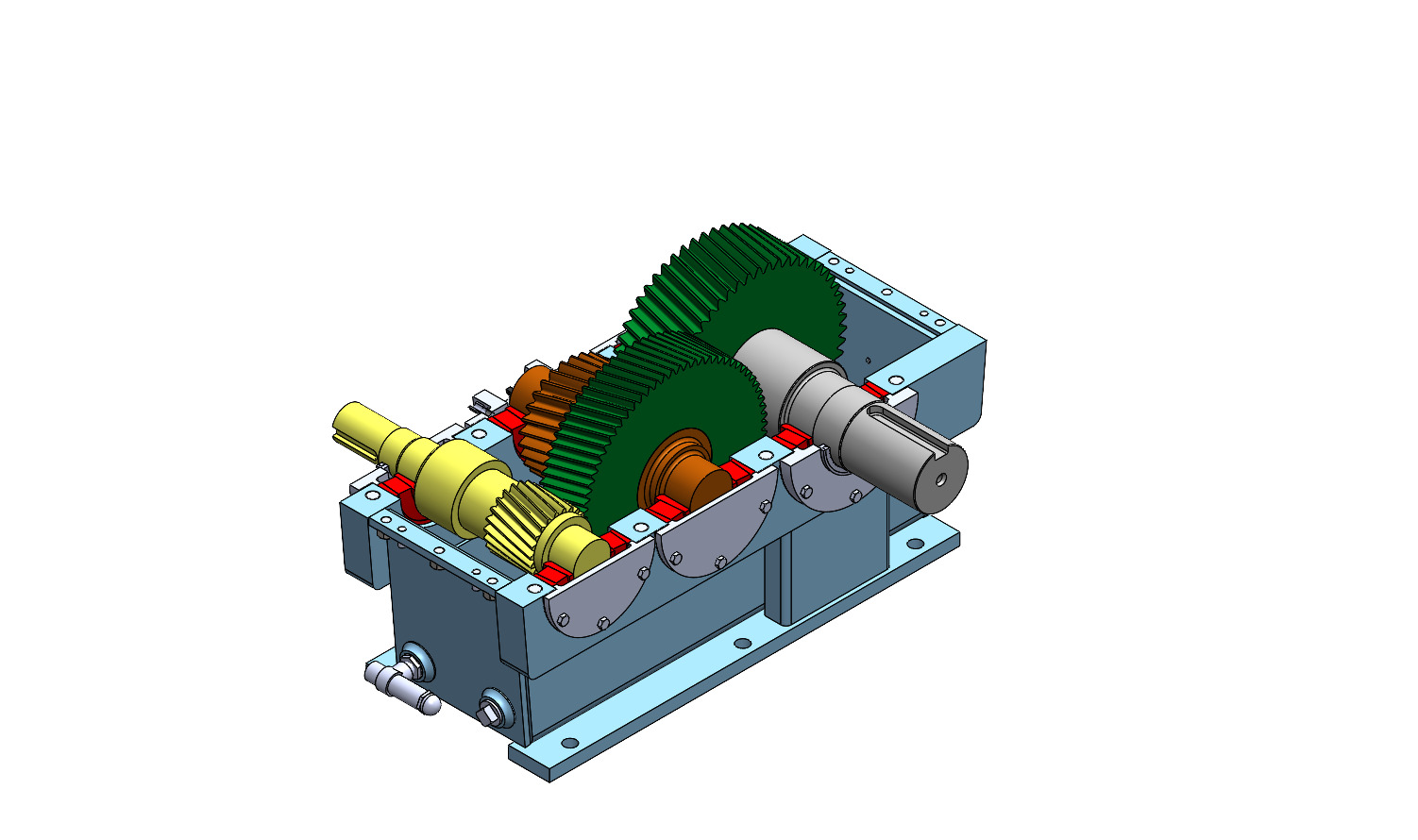

Parallel Offset Gearboxes

Cooling tower gearboxes

Guided selection driven by a simple form that will automatically calculate your optimal cooling tower gear drive for your specific application.

Pump Gearboxes

Our simple form requires only four inputs to generate your optimal pump gear drive selection and provide you with detailed specifications to fit your pumping application.

High-speed gearboxes

Our self-service tool will help your engineers design the ideal high-speed gearbox for your application. Our high-speed gearboxes can be designed to handle up to 80,000 HP.

Parallel Offset Gearboxes

With four simple inputs, our configuration tool will automatically calculate specifications to build your optimal parallel offset gearbox.