Keep your mission-critical mining operations on schedule with Standard Machine® and Philadelphia Gear®. Our teams provide the facilities, engineering muscle, and over 175 years of combined industry experience to support complex equipment for both surface and underground operations across the world’s harshest mining environments.

From mining potash, coal, and copper to iron ore, lithium, precious metals and more — access end-to-end gear design and manufacturing, inspections and repairs, and onsite technical services from our longtime experts.

With a deep engineering bench and manufacturing capabilities across our facilities, we deliver repair, parts, and design services for equipment including mining shovels and excavators. And as the OEM for Western Gearboxes, Westech Gearboxes, and Hamilton Gear, we provide superior support for our legacy brands, as well as reverse engineering and field service for any brand, any time, for your toughest applications.

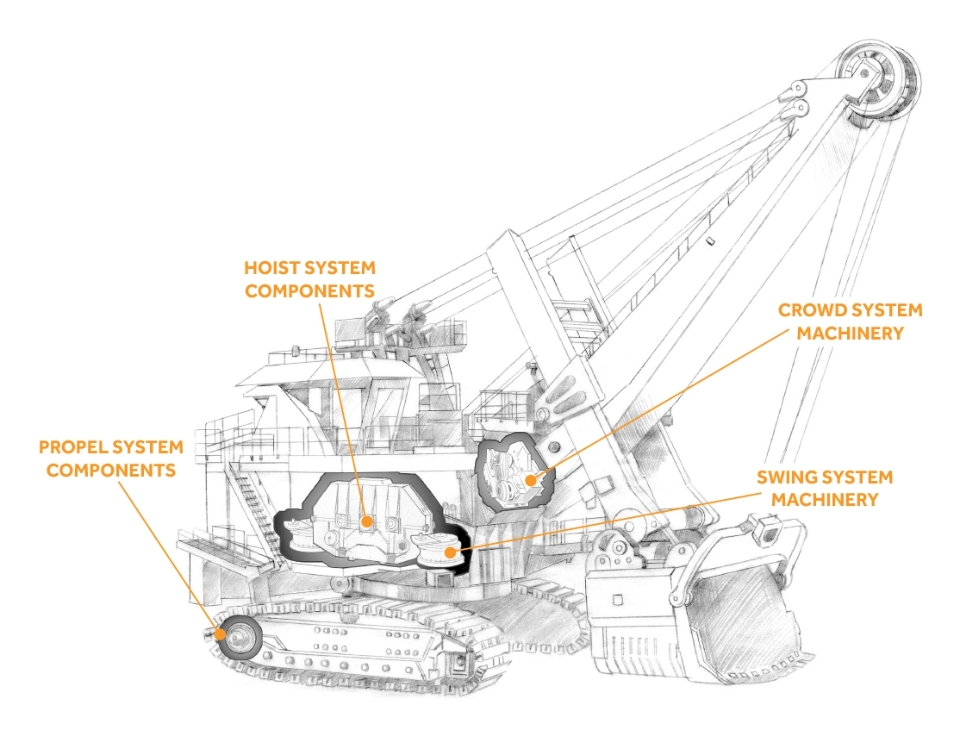

COMPLETE COVERAGE FOR YOUR MINING OPERATIONS

PROPEL SYSTEM COMPONENTS

- Planetary gear transmission

- Drive shafts

- Custom machining of critical parts and spares

HOIST SYSTEM COMPONENTS

- Motors and blowers

- Hoist transmission

- Hoist brake and drum gear

- Open gearing

CROWD SYSTEM MACHINERY

- Crowd transmission

- Brake and limit switch

- Rack pinions

- Shipper shafts

SWING SYSTEM MACHINERY

- Planetary transmission

- Swing shafts and pinions

- Swing rack gear

- Upper and lower roller paths

OUR GEARBOX CAPABILITIES FOR MINING

• Atlas Copco replacement parts

• Bevel helical gear roller mill drives

• Blast hole drill parts

• Bucyrus Erie parts

• Bucyrus Erie replacement parts

• Bull gears

• Caliper breaks

• Cooler tower gearbox replacement

• Cooler tower parts replacement

• Crowd pinion

• Dragline parts

• Dryer gears

• Electric shovel

• Gearbox repair

• Gear drive repair

• Gearbox design

• Gear drive design

• Gear drive manufacturing

• Gear cutting

• Gear design

• Gear grinding

• Gear inspections

• Gear manufacturing

• Gear regrinding

• Girth gears

• Ground gears

• Helical gears

• Internal flywheels

• Joy Global mining parts

• Kiln gears

• Low-speed backstops

• Marion parts

• Marion replacement parts

• Mill gears

• Mining replacement parts

• Mining shovel drill assembly

• Open gears

• P&H replacement parts

• Parallel shaft gears

• Propel transmission

• Right-angle gearboxes

• Ring gears

• Rotary cooler ring gears

• Rotary dryer ring gears

• Shovel transmission

• Spiral bevel gears

• Straight bevel gears

• Surface mining parts

• Swing transmission

• Worm gears

JOIN HUNDREDS OF SATISFIED CUSTOMERS

EXPLORE MINING RESOURCES

Case Studies

Brochures

Brochures

PROVEN SOLUTIONS FOR YOUR COMPLETE DRIVETRAIN SYSTEMPhiladelphia Gear operates at the core of critical applications, providing a complete range of custom-engineered mining gearbox products and services to keep your mining operations running reliably.

-

1

Gearbox repair

-

2

New and replacement gearbox expertise

-

3

Gearbox replacement parts

-

4

Onsite technical services

-

5

Drivetrain solutions

1 Gearbox repair

Any gear brand. Any time. Discover our world-class inspection, overhaul, and upgrade services.

2 New and replacement gearbox expertise

Prevent unplanned downtime with advanced engineering and design processes backed by over a century of manufacturing expertise. We can help with gearboxes for mining.

3 Gearbox replacement parts

Save time and eliminate worry knowing your mining gearbox parts are built to exacting OEM specifications, operating as well as, or better than, the originals.

4 Onsite technical services

Focus on your core business – our experts come to your location. Explore gearbox installation, repair, alignment, emergency services, and more.

5 Drivetrain solutions

As part of Timken Power Systems, we deliver a complete suite of electromechanical products and services from one trusted source.

Philadelphia Gear operates at the core of critical applications, providing a complete range of custom-engineered mining gearbox products and services to keep your mining operations running reliably.

-

1Gearbox repair

-

2New and replacement gearbox expertise

-

3Gearbox replacement parts

-

4Onsite technical services

-

5Drivetrain solutions

1 Gearbox repair

Any gear brand. Any time. Discover our world-class inspection, overhaul, and upgrade services.

2 New and replacement gearbox expertise

Prevent unplanned downtime with advanced engineering and design processes backed by over a century of manufacturing expertise. We can help with gearboxes for mining.

3 Gearbox replacement parts

Save time and eliminate worry knowing your mining gearbox parts are built to exacting OEM specifications, operating as well as, or better than, the originals.

4 Onsite technical services

Focus on your core business – our experts come to your location. Explore gearbox installation, repair, alignment, emergency services, and more.

5 Drivetrain solutions

As part of Timken Power Systems, we deliver a complete suite of electromechanical products and services from one trusted source.

KEEP YOUR MINING OPERATIONS MOVING. CONTACT OUR EXPERTS TODAY. We’re standing by to help with your most complex mining challenges. Email MiningSME@philagear.com for direct contact to our expert mining specialists today.

CONTACT US

We’re standing by to help with your most complex mining challenges. Email MiningSME@philagear.com for direct contact to our expert mining specialists today.