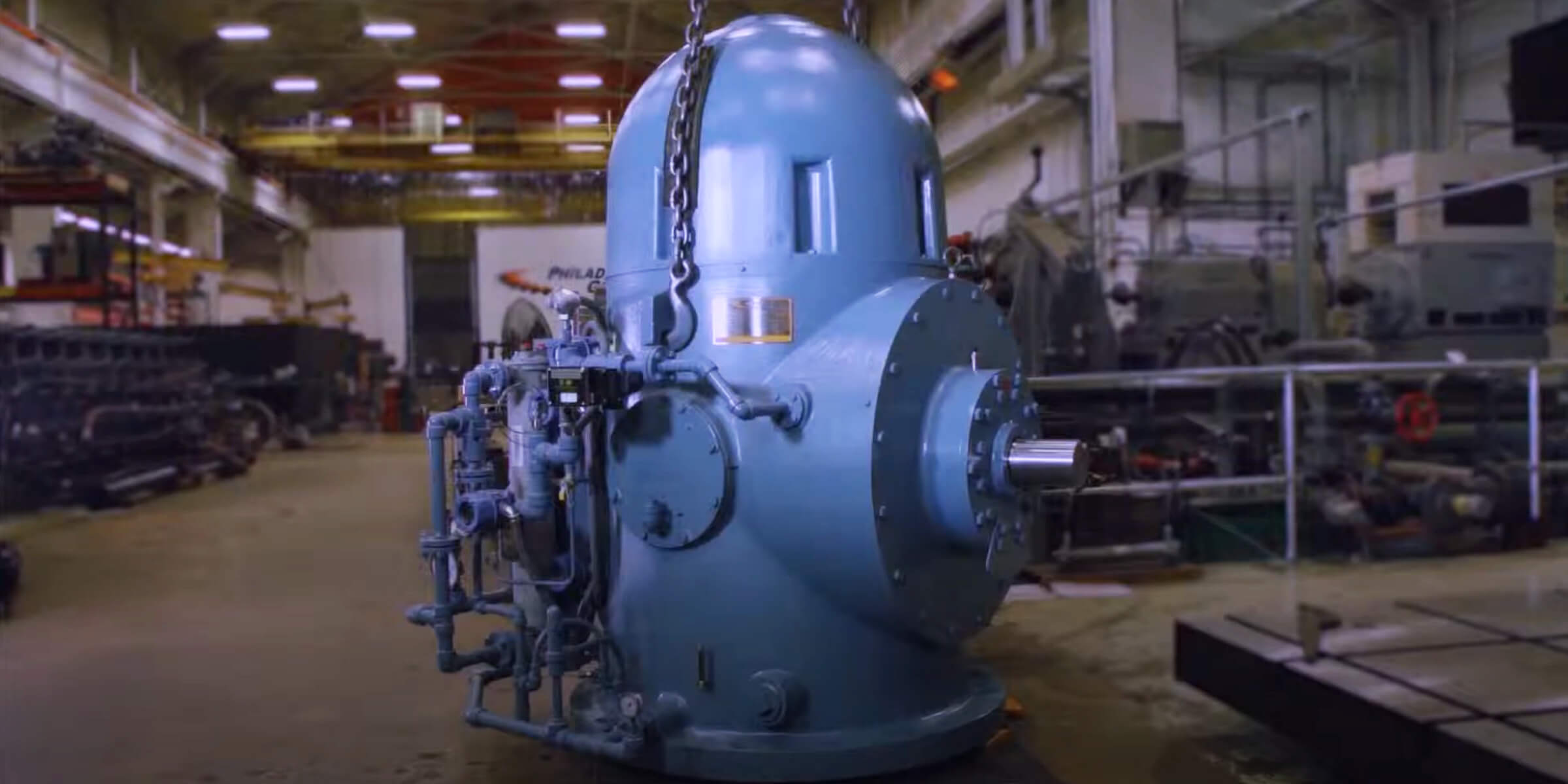

Bring over 130 years of gearbox and power transmission reliability to your operations. Philadelphia Gear® delivers trusted pump gearboxes, support, and repairs to a wide variety of critical industries and applications.

Municipal pump stations for managing excess rainwater. Low-head hydroelectric applications for generating power. Lock and dam installations managing water barrier gates. Whatever your pump gearbox challenge, our experts deliver top-quality solutions that boost performance and reliability — all backed by a 5-year warranty to protect your peace of mind.

PUMP DRIVES KEEP YOUR OPERATIONS MOVING

Need to transport, store, or condition water? Horizontal or vertical pumps get water where it needs to go. However, the pumps’ speeds are often incompatible with the speed of its driving motor. That’s where pump gearboxes come into play.

Philadelphia Gear works closely with your team to provide pump drives that keep your equipment running at the correct speeds — and at maximum efficiency.

Depending on shaft orientations, we allow horizontal drivers to interface with vertical pumps, and vice versa. And leveraging our extensive design experience in helical and spiral bevel gearing, we will manufacture, refurbish, and upgrade standard and custom-engineered drives for any ratio or configuration.

Don’t forget to try our pump drive configuration tool to develop gearbox sizing for your specific application: Pump Drive – Philadelphia Gear

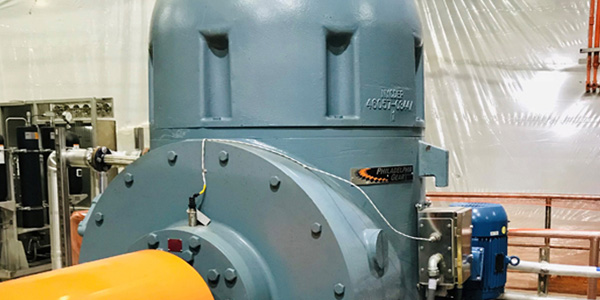

A HIGHER STANDARD FOR PUMP DRIVES

We engineer our drives to meet or exceed the requirements of the American Gear Manufacturers Association (AGMA). Our industry-leading solutions include the following features:

- Gears and pinions designed with an internally supported pinion gear to reduce deflection

- Durable heat-treated alloy steel drive shafts

- Splash or pressure systems, depending on application

- Custom pin- and ramp-style backstops to prevent damage caused by reverse rotation

COMPREHENSIVE SOLUTIONS AND PUMP GEARBOX REPAIR

- Centrifugal and Archimedes screw pumps

- Fireplug pump drives

- Vertical offset pump drives

- Horizontal input, vertical output reduction pump drives

- Spiral bevel vertical drives with integrated lubrication systems

- Helical and spiral bevel gearing

- Manufacturing, refurbishing, and upgrades

- Servicing virtually all equipment sizes, ratios, and configurations

- New or replacement enclosed drives and parts

- Drivetrains

- Inspection and repair

- 24/7 emergency services

- Best-in-industry 5-year warranty for new builds

- Best-in-industry 3-year warranty for repairs

EXPLORE PUMP GEARBOX RESOURCES

CONFIGURATION TOOL

DON’T LEAVE YOUR PUMP GEARBOX AT RISK. CONTACT OUR EXPERTS TODAY. We’re standing by to help prevent downtime — and keep your operations running reliably.

Contact Us

We’re standing by to help prevent downtime — and keep your operations running reliably.