Come to us for OEM support for Philadelphia Gear® brand gearboxes and parts. Our five Philadelphia Gear facilities (in the U.S.) and Standard Machine® (in Canada) are the only authorized manufacturing and repair facilities that have access to and maintain the intellectual property for Philadelphia Gear®, and our legacy brands, Hamilton Gear®, Western Gear®, and Westech®.

With access to a massive database of these brands’ drawings and original designs, we ensure zero cut corners and total peace of mind. Our experts deliver genuine replacement parts and gearboxes to match the original’s footprint, functionality, and design — so you can avoid faulty imitations and get your operations running quickly.

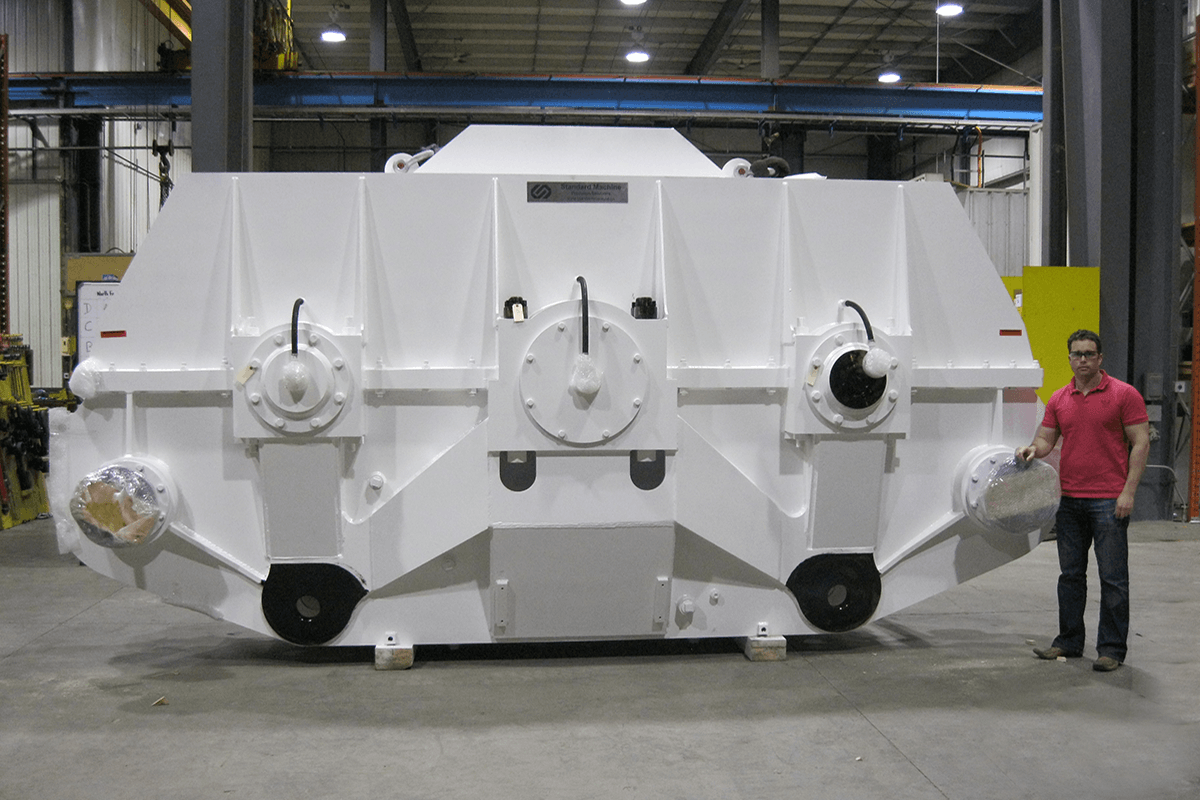

Standard Machine

Tap into the industry’s broadest and deepest gearbox capabilities and expertise. As part of the Timken Power Systems’ network, Philadelphila Gear and Standard Machine work together to provide the experience and facilities to support North America’s most complex challenges.

Two brands working together and leveraging over 175 years of combined expertise, extends our reach to support the manufacturing and repair of mining equipment globally. And with Standard Machine having access to Philadelphia Gear’s intellectual property, 24/7 emergency service, engineers, training center, and database, they can service any Philadelphia Gear, Western, WesTech, and Hamilton gearbox in Canada.

Western Gear

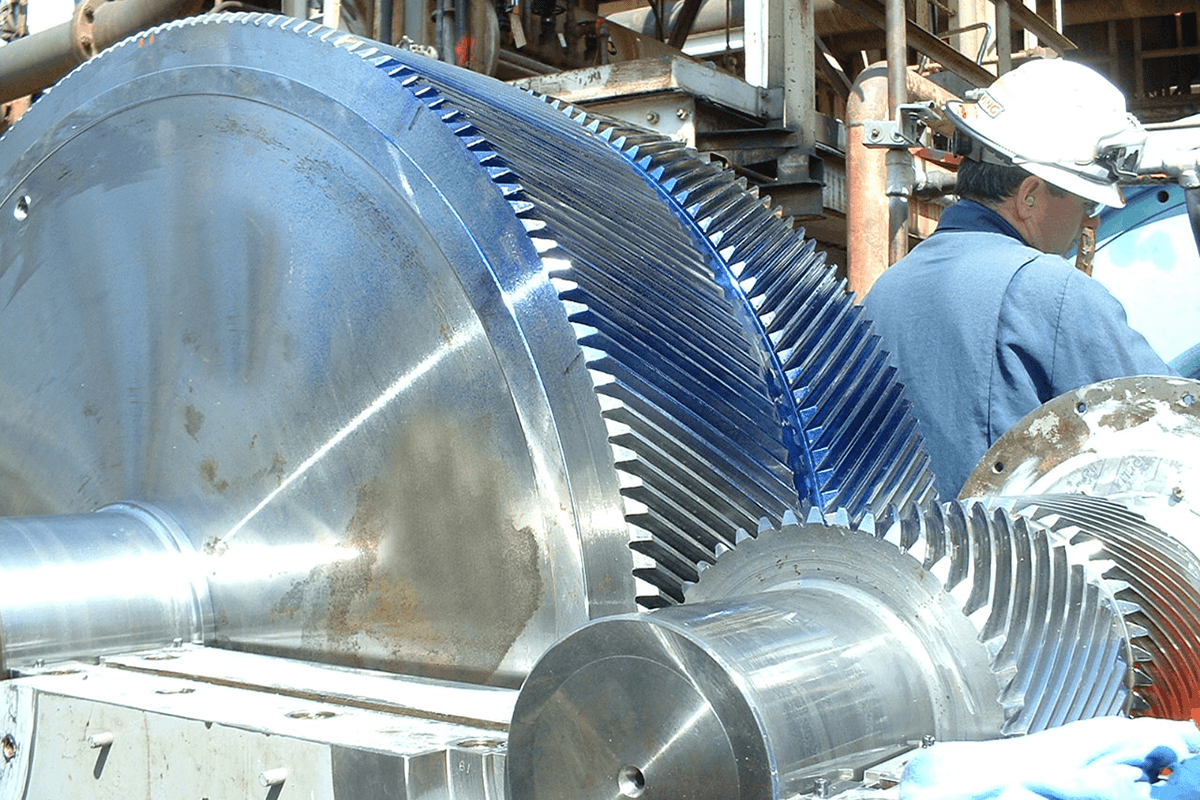

Access complete gearbox repair and gear manufacturing services for Western Gear’s full line of industrial high-speed gearboxes, speed reducers, and marine gearboxes. As their official original equipment manufacturer, Philadelphia Gear is an industry leader for Western Gear support, offering superior design, repair, and in-house machining capabilities to get your equipment back in service quickly.

Western Gear’s precision machinery equipment is found in aerospace, maritime, pulp and paper, offshore operations, primary metals, and several other critical markets, with gearboxes spanning legacy brands including Speedmaster, Torqmaster, Seamaster, Straitline, Pumpmaster, and Millmaster.

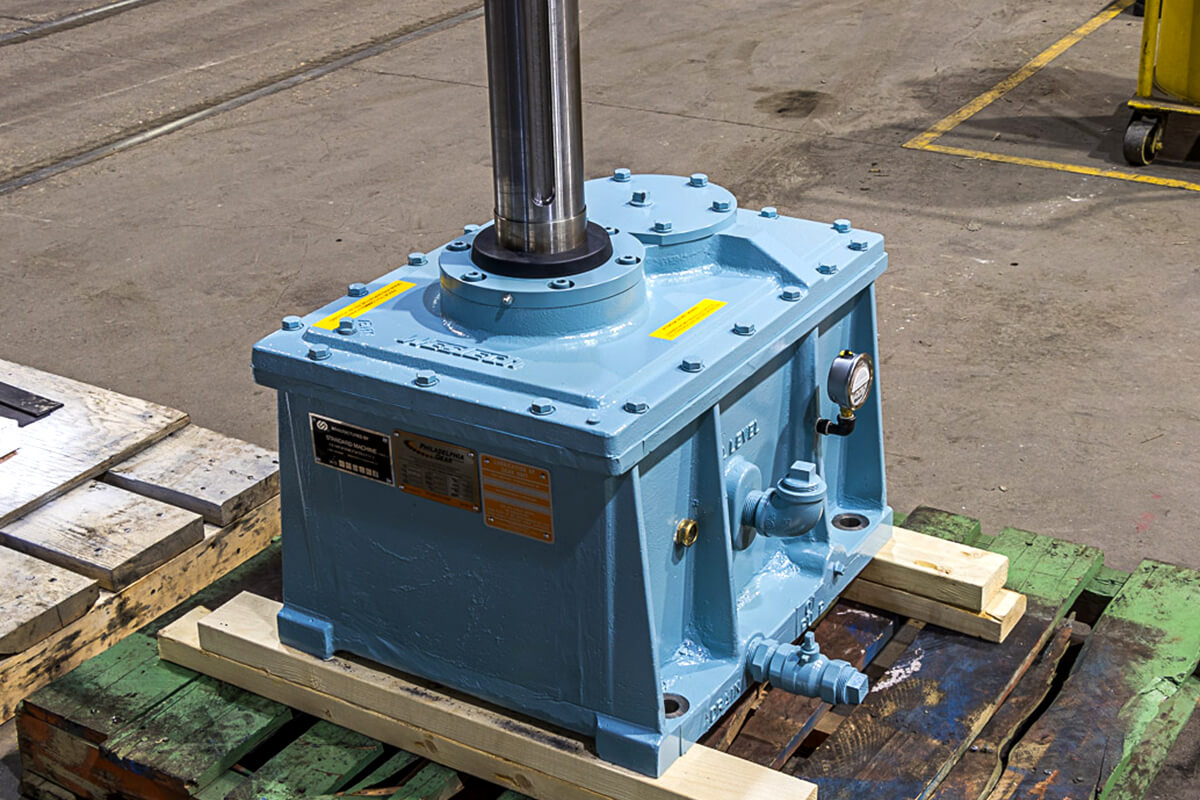

WesTech

Choose Philadelphia Gear, the original equipment manufacturer for WesTech repairs. Philadelphia Gear delivers complete gearbox repair, design, and manufacturing services for WesTech high-speed gearboxes, speed reducers, and marine gearboxes, backed by our unmatched team of design engineers, customer service support staff, and expert machinists. Our comprehensive gearbox repair services include a full inspection of all gears and other rotating elements in your Westech enclosed drive.

Formerly Western Gear Corporation, WesTech equipment is found in mining conveyors, mixing applications, steel mills, aerospace, maritime, pulp and paper, offshore operations, and several other heavy industrial markets. Its legacy line of products includes the brands Speedmaster, Torqmaster, Seamaster, Straitline, Pumpmaster, and Millmaster.

Onsite Technical Services (OTS)

Sometimes, you can’t simply pull a critical component out of service and ship it to a repair facility hundreds of miles away. Philadelphia Gear’s OTS program is the one-stop-shop, onsite solution to gearing and power transmission-related problems. With one call to Standard Machine, we’ll define a scope of work that can include rebuilding gearboxes “in place,” re-boring the housings on location, plus any necessary rigging operations, mobilization of manpower, and equipment transportation.

As the leader in industry for gearbox repair services, Standard Machine is proud to cover everything customers need via OTS, from A to Z.

- Alignment services including laser, optical and reverse

- Balancing of rotating elements

- Complete on-site gearbox overhauling capability

- Diagnostic services with full customer documentation

- Engineering and reverse engineering of components

- Failure analysis

- Grouting of foundations and equipment

- Housing re-boring

- In-place machining

- Journal and gear hardness checks

- Keyway cutting

- Line boring

- Non-destructive testing including magnetic particle inspection

- Millwright services

- Oil sampling and analysis

- Preventative and predictive maintenance programs

- Quality and safety certifications

- Removal and reinstallation of gearboxes and related equipment

- Spare parts and drive exchange programs available

- Temperature readings by infrared laser

- Ultrasonic testing

- Vibration analysis

- Welding

- X-factor of more than a century’s worth of experience

- Yellow gear marking compound for tooth contact checks

- Zero defect operating philosophy

Raise your standard for OEM gearboxesSee for yourself why Philadelphia Gear® is the first choice for the world’s leading original equipment manufacturers. Connect with one of our experts today.

CONTACT USREQUEST A PART

See for yourself why Philadelphia Gear® is the first choice for the world’s leading original equipment manufacturers. Connect with one of our experts today.