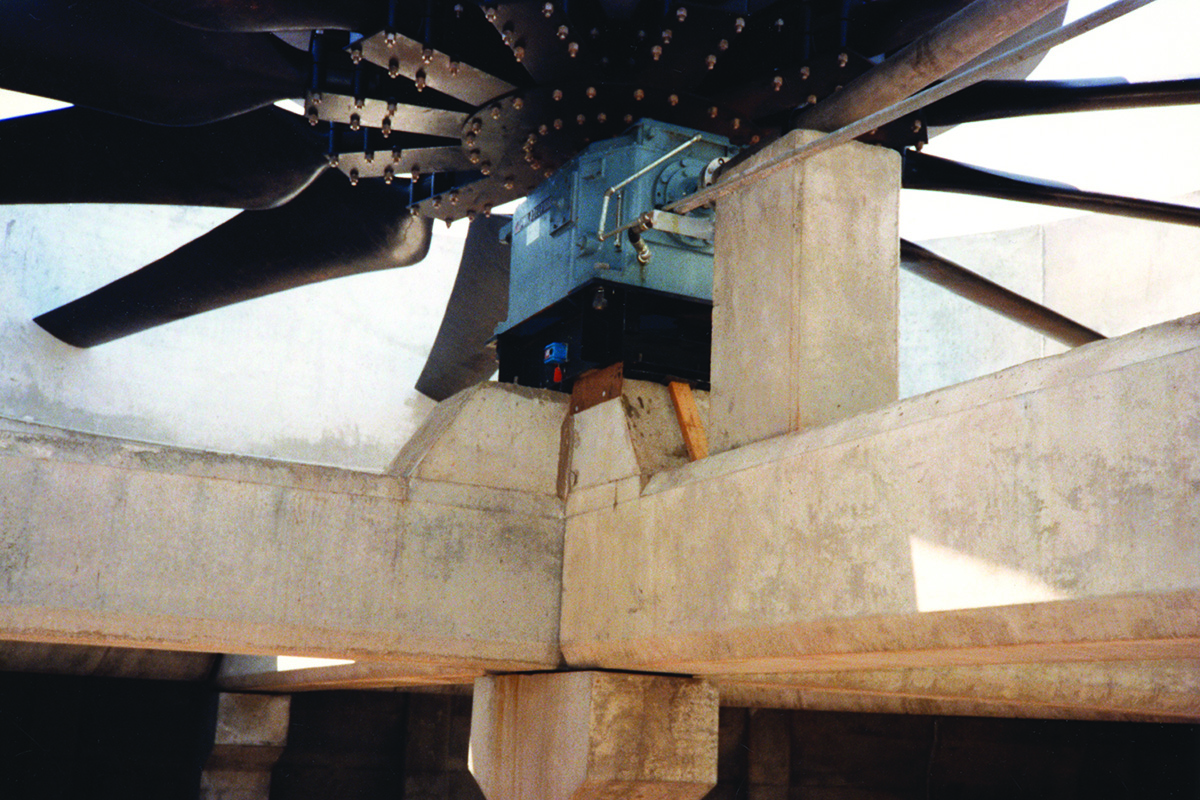

For over 50 years, refinery and power plant operators have chosen Philadelphia Gear® for cooling tower gearboxes to drive massive fans that keep hot air moving where it needs to go — out of their facilities.

Our single reduction and double reduction units have powered air evacuation for clients across multiple industries, thanks to a higher standard of construction. Our units feature precise spiral-bevel gearing, easy maintenance access, and a best-in-industry 5-year warranty unmatched by other cooling tower gearbox manufacturers.

PHILADELPHIA GEARBOXES ARE BUILT TO LAST. AND LAST.

At the heart of every cooling tower gearbox we design are precision-engineered, spiral bevel gears that achieve even tooth-to-tooth spacing through the continuous indexing cyclo-palloid method of generating gear teeth. Day after day, our drives produce less sound and vibration than traditional cut and lapped alternatives — resulting in longer, more dependable performance.

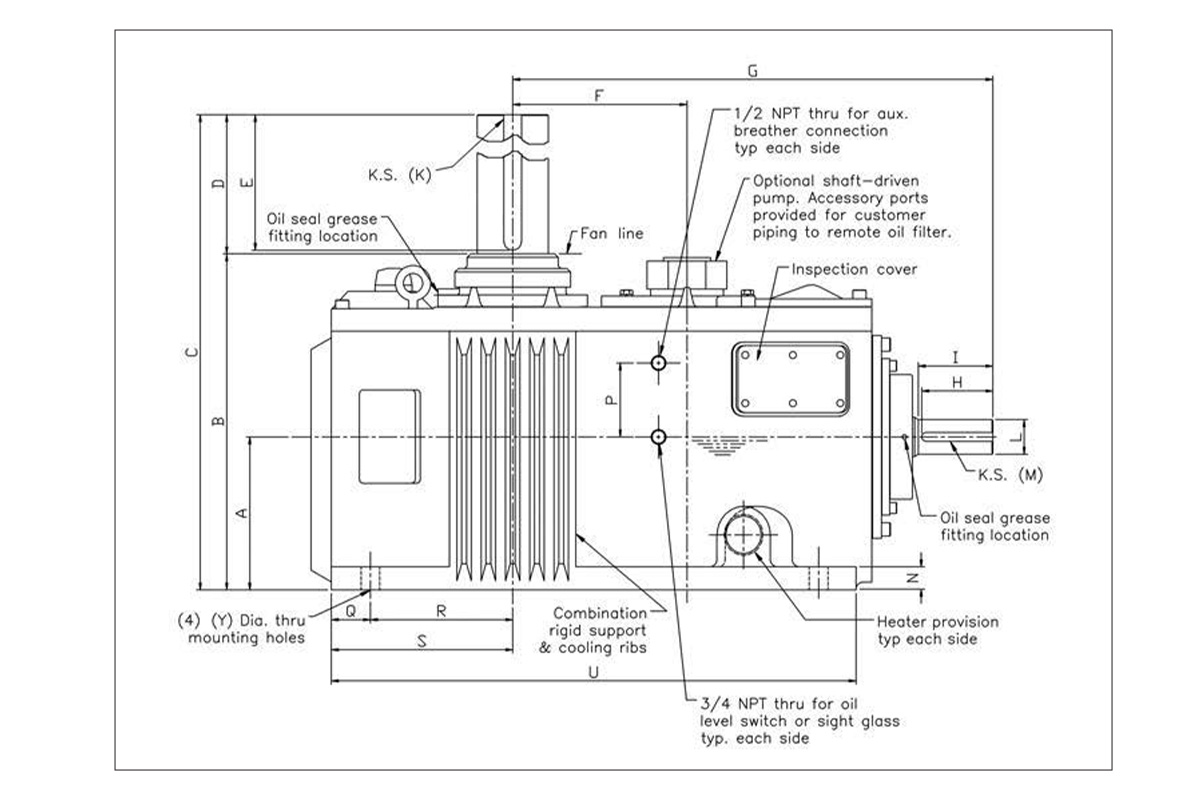

Drive shafts in both single- and double-reduction units are heat-treated, precision-ground alloy steel. We employ premium tapered roller bearings to meet or exceed AGMA and CTI standards. And we make maintenance easy with strategically located inspection covers allowing fast and clear visual lines to gears, bearings, and the oil reservoir.

SINGLE REDUCTION UNITS FOR COOLING TOWER FANS

Available in 15 sizes, with output thrust capacities ranging from 550 to 7,100 pounds, Philadelphia Gear’s single reduction cooling tower gearbox units are splash-lubricated and protected by heavy-duty housings machined for precise, permanent alignment of gears, shafts, and bearings.

DOWNLOAD SPEC SHEETDOUBLE REDUCTION UNITS FOR COOLING TOWER FANS

Available in five sizes, with output thrust capacities ranging from 3,000 to 22,000 pounds, Philadelphia Gear’s double reduction cooling tower gearbox units are both splash-and pressure-lubricated. We design our housings to minimize deflections due to external thrust loads by using only the best, field tested materials. As with our single reduction units, double reduction units are machined with lifetime component alignment in mind.

DOWNLOAD SPEC SHEET

THE BEST WARRANTY YOU MAY NEVER NEED

Gain the peace of mind that comes with the longest, most comprehensive cooling tower gearbox warranty in the world. All new Philadelphia Gear gearboxes come with a 5-year warranty — no matter how challenging the application or operating environment.

We don’t expect you’ll need it. But we stand behind more than a century of manufacturing experience, state-of-the-art materials, and world-class design engineering because we know your operations can’t afford cooling tower downtime.

OPTIONAL GEARBOX FEATURES

- Motor-driven pump

- Sprag-type backstop

- Breathers for corrosive atmospheres

- Special exterior paints

- Corrosion-resistant and heavy-duty external hardware

- Special shaft extensions

- Intermediate and special ratios

- Oil immersion heater

- Oil pressure switch

- Oil level switch

- Oil temperature switch

- Vibration switch

- Seal splash guards

- Custom materials for housing and shafts

- Wear sleeves for seal journals

DON’T RISK YOUR COOLING TOWER GEARBOX. CALL PHILADELPHIA GEAR.Whatever the load, whatever the spec, our engineers are ready to take on and solve your challenge today.

CONTACT US

Whatever the load, whatever the spec, our engineers are ready to take on and solve your challenge today.