Return your gearbox to peak performance with end-to-end support from Philadelphia Gear®. When different providers service different stages of the gear repair process, conflicting approaches lead to dissatisfactory results. That’s why we identify and repair gearbox issues from start to finish, ensuring dependable repairs — and performance.

With five regional service and manufacturing facilities, our expert technicians are equipped to service a variety of gearbox configurations and critical applications. And leveraging 130 years of trusted gearbox expertise, we set the industry standard for gearbox manufacturing and maintenance. We’re ready to handle all your industrial gearbox maintenance and repair needs.

TERMS AND CONDITIONS

DISCOVER OUR END-TO-END REPAIR PROCESS

-

1

Disassembly and cleaning

-

2

Inspection and measurement

-

3

Engineering evaluation and recommendations

-

4

Upgrades and modifications

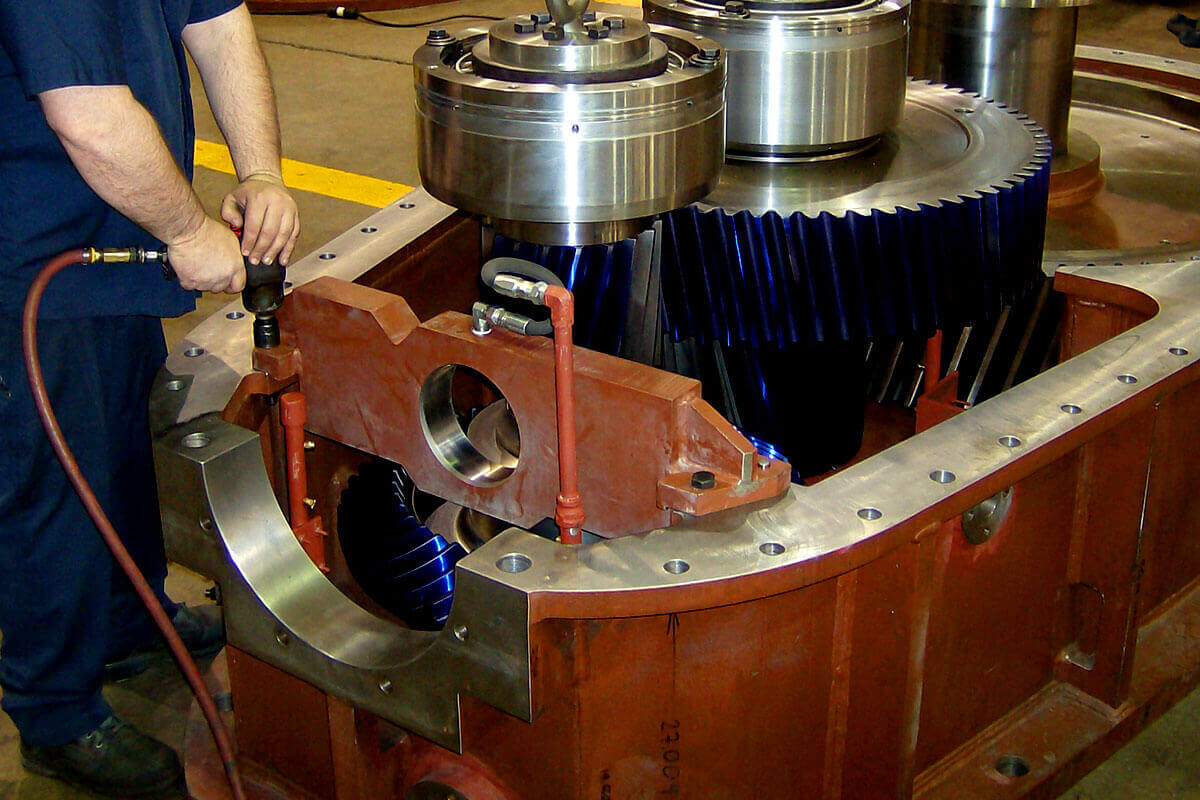

1 Disassembly and cleaning

Address gearbox problems before they begin with full disassembly and cleaning from Philadelphia Gear. Our skilled technicians provide a full suite of diagnostic services to ensure your operations can continue running in the harshest conditions.

2 Inspection and measurement

Eliminate long-term gearbox issues with precise inspections from Philadelphia Gear. Each of our five regional service and manufacturing facilities are equipped to document the state of your gearbox – and identify root causes of its potential failure.

3 Engineering evaluation and recommendations

Whether you’re looking to address gearbox vibration, enhance efficiency, increase horsepower ratings, or improve speed and control, our team delivers the expertise to evaluate your gearbox and guide you toward the proper solution.

4 Upgrades and modifications

Our expert technicians will let you know what changes best support the needs of your specific gearbox and operation. Rest easy knowing our custom recommendations are backed by our proven, in-depth process.

-

1Disassembly and cleaning

-

2Inspection and measurement

-

3Engineering evaluation and recommendations

-

4Upgrades and modifications

1 Disassembly and cleaning

Address gearbox problems before they begin with full disassembly and cleaning from Philadelphia Gear. Our skilled technicians provide a full suite of diagnostic services to ensure your operations can continue running in the harshest conditions.

2 Inspection and measurement

Eliminate long-term gearbox issues with precise inspections from Philadelphia Gear. Each of our five regional service and manufacturing facilities are equipped to document the state of your gearbox – and identify root causes of its potential failure.

3 Engineering evaluation and recommendations

Whether you’re looking to address gearbox vibration, enhance efficiency, increase horsepower ratings, or improve speed and control, our team delivers the expertise to evaluate your gearbox and guide you toward the proper solution.

4 Upgrades and modifications

Our expert technicians will let you know what changes best support the needs of your specific gearbox and operation. Rest easy knowing our custom recommendations are backed by our proven, in-depth process.

KEEP YOUR OPERATIONS RUNNING SMOOTHLY. CONTACT PHILADELPHIA GEAR TODAY. We’re standing by to help with your most complex gearbox challenges. Connect with one of our expert specialists today.

CONTACT US

We’re standing by to help with your most complex gearbox challenges. Connect with one of our expert specialists today.