Get water where it needs to go, fast – any ratio, any configuration. With over 130 years of mechanical expertise, and as part of the Timken Power Systems network, Philadelphia Gear® manufactures and services gearboxes, along with providing generator and electric motor repair expertise. The result: one trusted partner to help tackle the water management industry’s harshest applications.

Our equipment operates at the center of critical operations, including flood control, gate systems, environmental reclamation, wastewater treatment, and potable water processing – all backed by our industry-best warranty. And with six independently ISO 9001:2015 certified facilities in North America, you can get the customized solutions you need to keep more water moving.

TRUSTED WATER MANAGEMENT SOLUTIONS ACROSS FOUR CRITICAL AREAS

Find expert support for your specific application. To see our hydroelectric solutions, click here.

FLOOD CONTROL

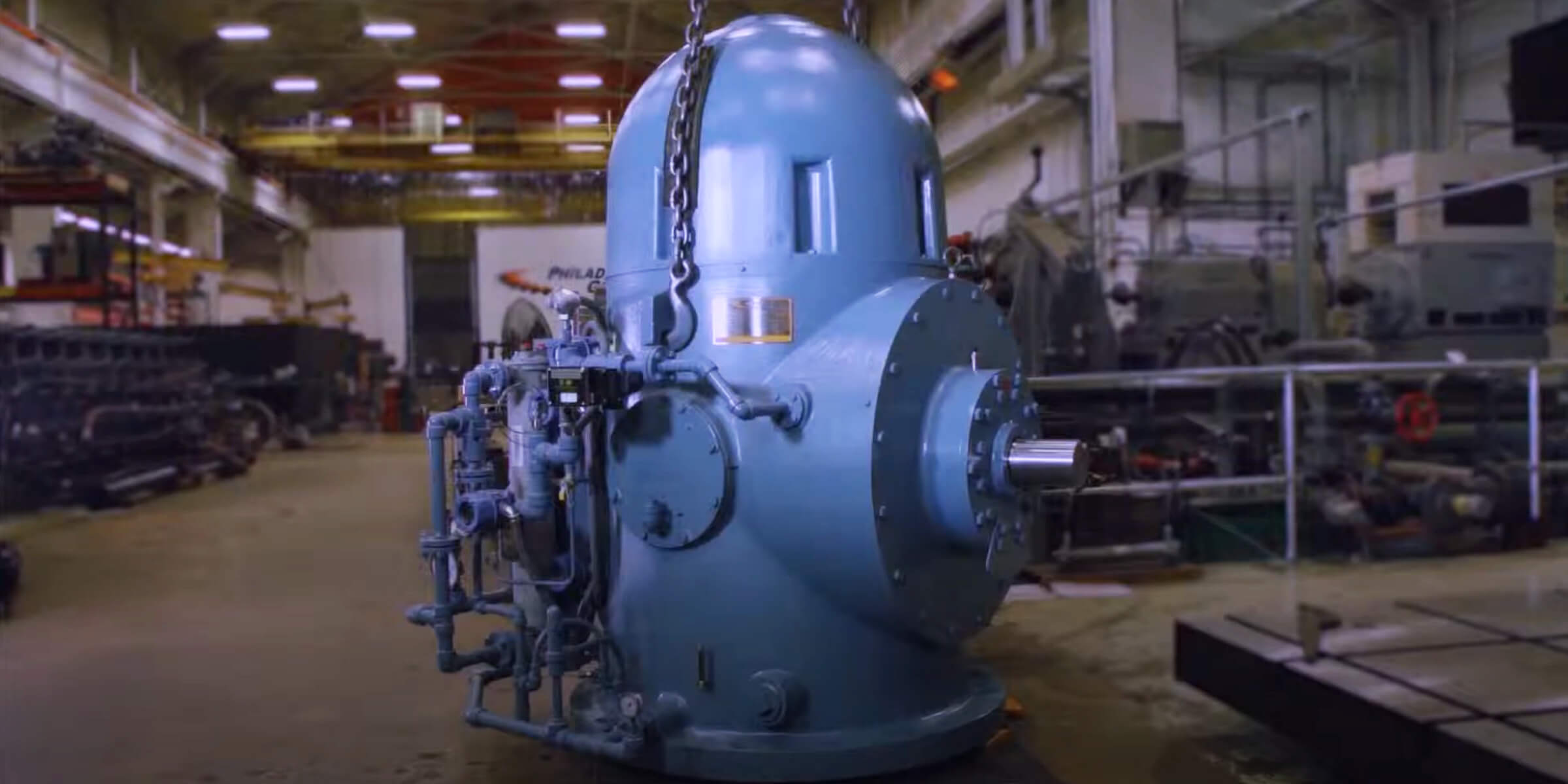

Remove floodwater quickly with reliable, engineered gearboxes for any pump configuration. We provide new equipment, pump gearbox repair, and emergency services as well as submersed gearbox recovery procedures to help your municipal pump station manage stormwater overflow.

GATE SYSTEMS

Whether it’s keeping ships moving with lock systems or managing water at large reservoirs, our rugged gearboxes lift massive gates at waterways throughout the world.

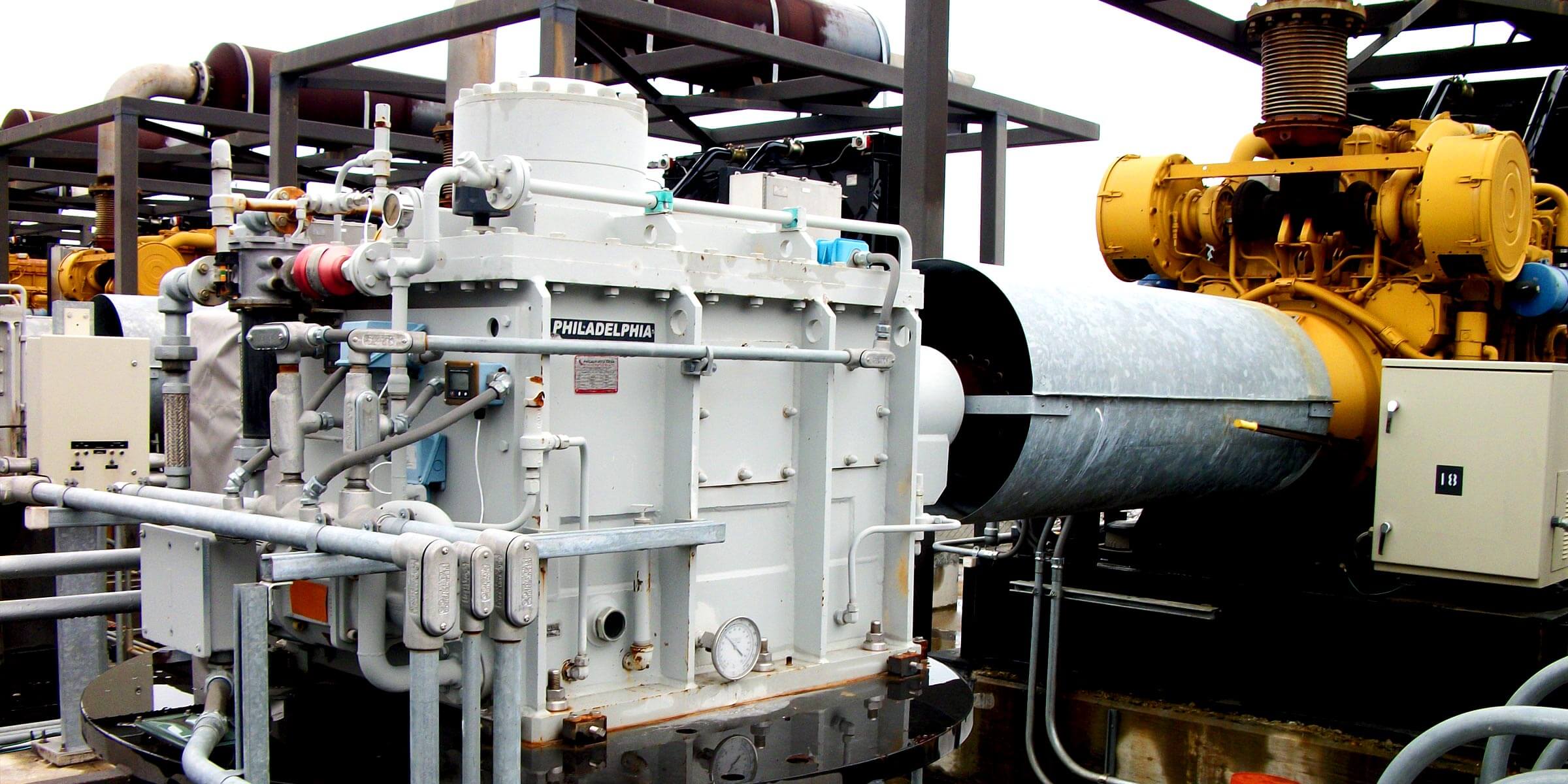

WASTEWATER

Keep water moving with a single source of comprehensive gearbox, electric motor, and control system support for your high-volume pumps and other critical equipment.

POTABLE WATER

Ensure access to clean water in your community. Our gearbox provides the reliability to ensure drinking water gets to where it needs to go.

COMPLETE SUPPORT FOR YOUR WATER MANAGEMENT APPLICATION

- 1 MW to 15 MW generator repair hydroelectric installations

- AGMA-rated gearboxes and gears

- Archimedes screw pump gearboxes and gear drives

- API-rated industrial gearboxes and gears

- Cooling tower gears and industrial gearboxes

- Custom solutions

- Double helical industrial gears

- Double right-angle gears

- Electric motor repair

- Enclosed drives

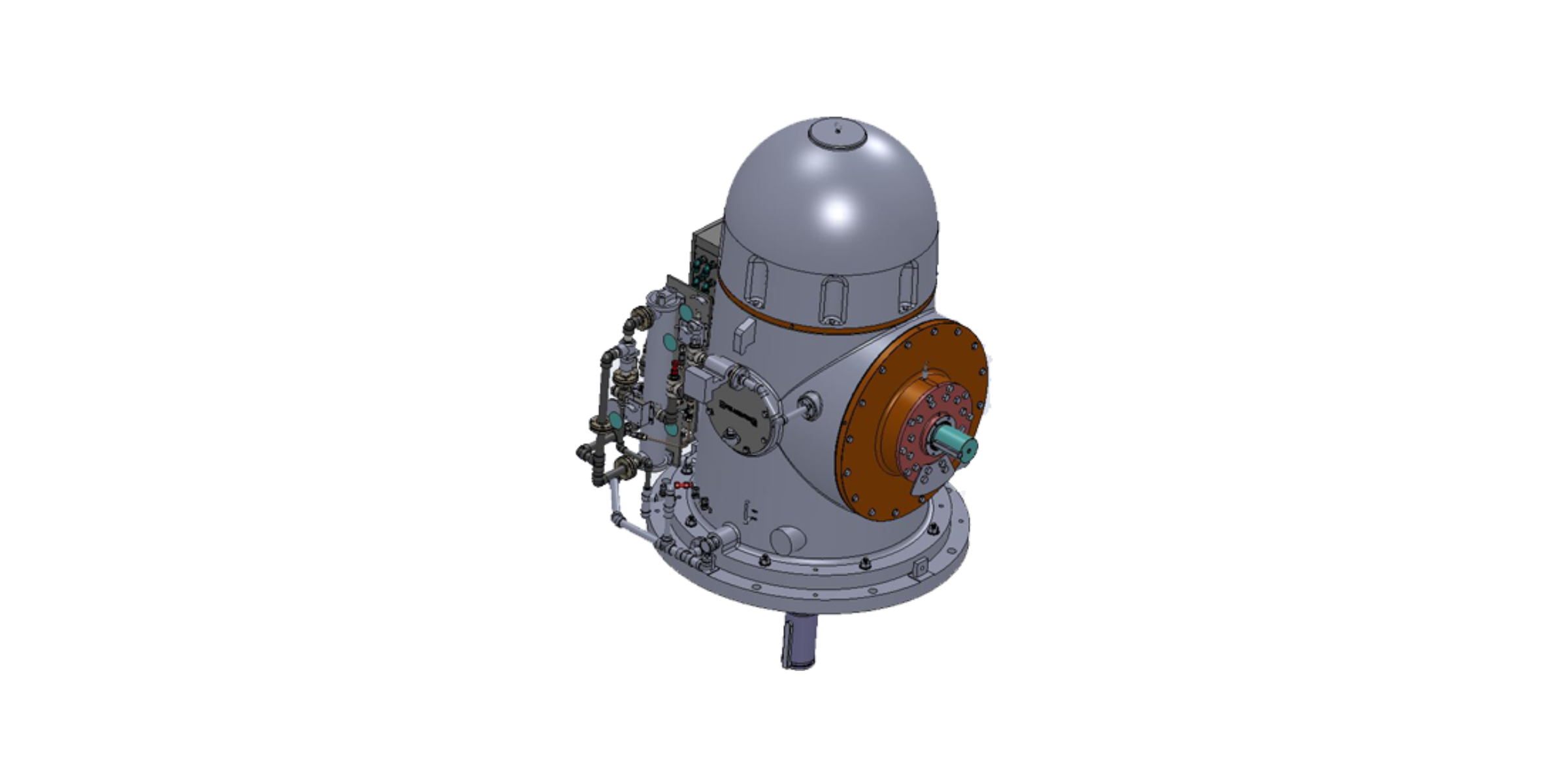

- Epicyclic gearboxes and planetary gear drives

- Fish ladder drives

- Gate drives

- Gear reducers

- Gearbox repair

- Gears for gate systems

- Gears to replace chain drives

- Generator repair

- Girth gears

- Helical gears

- High-speed industrial gears and gearboxes

- Hydroelectric speed increasers

- Lock and dam gears

- Low-speed gearboxes

- OEM direct interaction

- Open gearing

- Pinions

- Pump drives

- Pump Gearbox Repair

- Right-angle pump drives

- Right-angle gearboxes

- Reverse engineering

- Rotating equipment support

- Substantially engineered product

- Turbine gears and gearboxes

- Vacuum pump gears

- Virtual gear configuration

- Worm gears gate systems

JOIN HUNDREDS OF SATISFIED CUSTOMERS

EXPLORE WATER RESOURCES

CONFIGURATION TOOL

PROVEN SOLUTIONS FOR YOUR COMPLETE DRIVETRAIN SYSTEMPhiladelphia Gear operates at the core of critical applications, providing a complete range of custom-engineered products and services to keep operations running reliably.

-

1

Gearbox repair

-

2

New and replacement gearbox expertise

-

3

Gearbox replacement parts

-

4

Onsite technical services

-

5

Drivetrain solutions

1 Gearbox repair

Any gear brand. Any time. Discover our world-class inspection, overhaul, and upgrade services.

2 New and replacement gearbox expertise

Prevent unplanned downtime with advanced engineering and design processes backed by over a century of manufacturing expertise.

3 Gearbox replacement parts

Save time and eliminate worry knowing your parts are built to exacting OEM specifications, operating as well as, or better than, the originals.

4 Onsite technical services

Focus on your core business – our experts come to your location. Explore gearbox installation, repair, alignment, emergency services, and more.

5 Drivetrain solutions

As part of Timken Power Systems, we deliver a complete suite of electromechanical products and services from one trusted source.

Philadelphia Gear operates at the core of critical applications, providing a complete range of custom-engineered products and services to keep operations running reliably.

-

1Gearbox repair

-

2New and replacement gearbox expertise

-

3Gearbox replacement parts

-

4Onsite technical services

-

5Drivetrain solutions

1 Gearbox repair

Any gear brand. Any time. Discover our world-class inspection, overhaul, and upgrade services.

2 New and replacement gearbox expertise

Prevent unplanned downtime with advanced engineering and design processes backed by over a century of manufacturing expertise.

3 Gearbox replacement parts

Save time and eliminate worry knowing your parts are built to exacting OEM specifications, operating as well as, or better than, the originals.

4 Onsite technical services

Focus on your core business – our experts come to your location. Explore gearbox installation, repair, alignment, emergency services, and more.

5 Drivetrain solutions

As part of Timken Power Systems, we deliver a complete suite of electromechanical products and services from one trusted source.

MOVE MORE WATER, MORE RELIABLYWe’re standing by to help with your most complex water management challenges. Email WaterSME@philagear.com for direct contact to our expert water specialists today.

CONTACT US

We’re standing by to help with your most complex water management challenges. Email WaterSME@philagear.com for direct contact to our expert water specialists today.