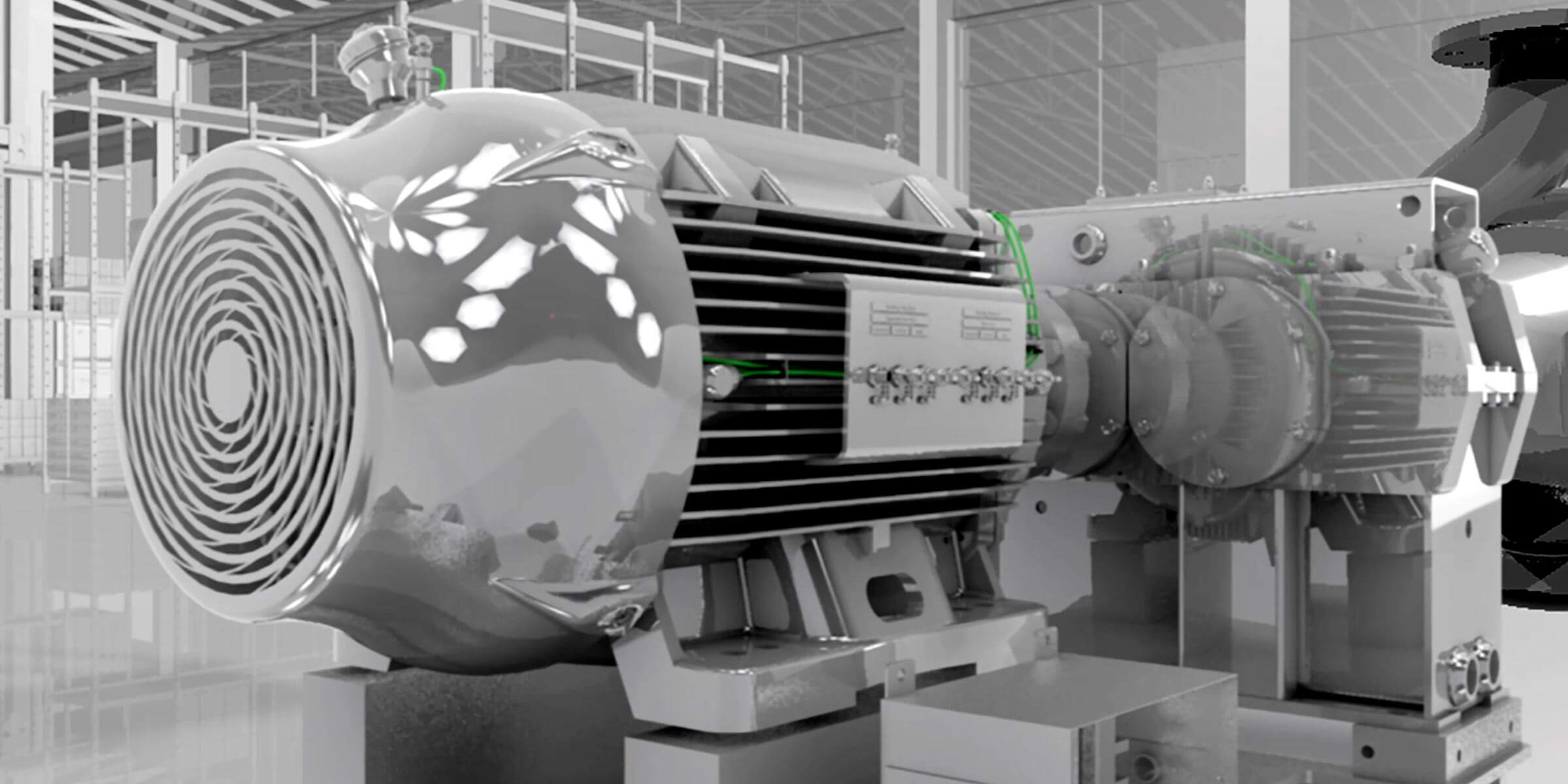

Keep the world more reliably powered with Philadelphia Gear®. From supporting machinery that extracts oil on land and offshore, to transporting and refining it to create essential products, we supply comprehensive support for your critical applications.

With end-to-end inspection and repair, replacement parts, onsite technical services, and drive train solutions, Philadelphia Gear ensures trusted performance for your operations — and the communities who rely on them.

TRUSTED PETROCHEMICAL SOLUTIONS ACROSS THREE CRITICAL AREAS

Find expert drivetrain support at every stage of the petrochemical industry’s process.

UPSTREAM: EXPLORATION AND EXTRACTION

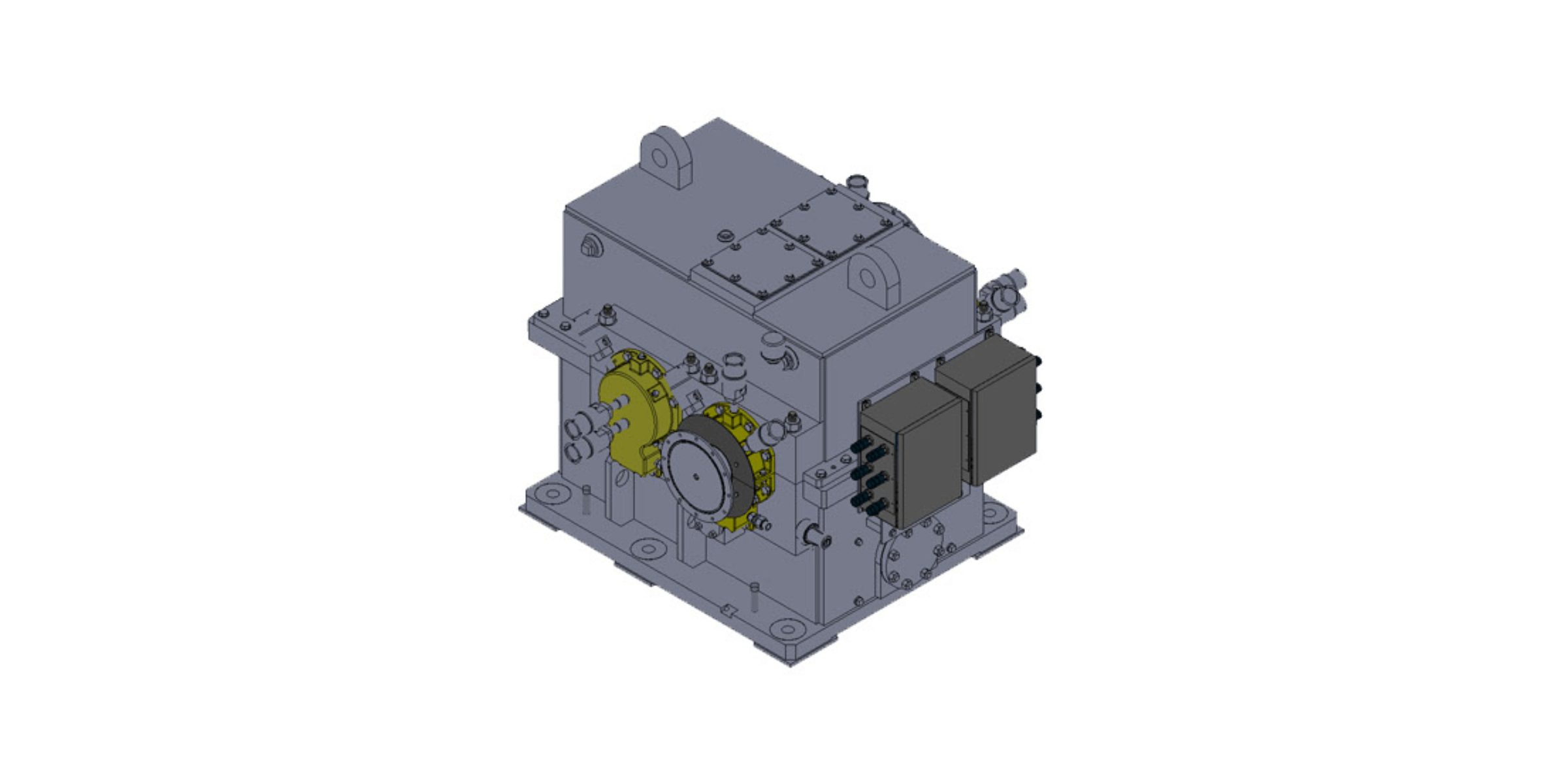

Get the high-speed compressor gearboxes, transmission equipment, and aftermarket support to ensure access to the resources that power our world.

MIDSTREAM: PIPELINES

Transport natural resources where they need to go. Since 1960, we’ve produced over 4,000 pump and compressor gearboxes, the majority of which are custom designed for supporting pipelines.

DOWNSTREAM: REFINERIES AND HYDROCARBON PROCESSING

Get reliable high- and low-speed pump gearboxes, high-speed compressor industrial gearboxes, single and double reduction cooling tower gearboxes, and blower and fan gearboxes— plus unrivaled aftermarket support. Our equipment helps refineries supply the materials used to make adhesives, detergents, fertilizers, pharmaceuticals, and other essential products.

COMPLETE SUPPORT FOR YOUR PETROCHEMICAL APPLICATION

- Blower gear drives

- Blower gearboxes

- Centrifugal pump drive

- Centrifugal pump drive repair

- Centrifugal pump gearbox

- Centrifugal pump gearbox repair

- Compressor drives

- Compressor gear drive repair

- Compressor gearbox repair

- Compressor gearboxes

- Compressor station gear drives

- Compressor station gearboxes

- Cooling tower gear drive repair

- Cooling tower gear drives

- Cooling tower gearbox

- Cooling tower gearbox repair

- Double-helical gearing

- Double-reduction cooling tower gearbox repair

- Double-reduction cooling tower gearboxes

- Fan drive repair

- Fan drives

- Fan gearbox repair

- Fan gearboxes

- Gear drive repair

- Gearbox repair

- High-speed gearbox repair

- High-speed gearboxes

- High-speed pump drive repair

- High-speed pump drives

- LNG pipeline centrifugal pump drive

- LNG pipeline centrifugal pump gearbox

- Low-speed gear drive repair

- Low-speed gear drives

- Low-speed gearbox repair

- Low-speed gearboxes

- Natural gas compressor drives

- Natural gas compressor gear drive repair

- Natural gas compressor gearbox repair

- Natural gas compressor gearboxes

- Pipeline compressor gear drives

- Pipeline compressor gearboxes

- Pipeline pump drives

- Pipeline pump gearboxes

- Pump drive repair

- Pump drives

- Pump gearbox repair

- Pump gearboxes

- Reciprocating pump drive

- Reciprocating pump drive repair

- Reciprocating pump gearbox

- Reciprocating pump gearbox repair

- Refinery cooling tower gear drive repair

- Refinery cooling tower gear drives

- Refinery cooling tower gearbox repair

- Refinery cooling tower gearboxes

- Refinery gear drive repair

- Refinery gearbox repair

- Right-angle gearbox

- Right-angle gearbox repair

- Right-angle gearboxes

- Right-angle pump drives

- Right-angle refinery gear drive repair

- Right-angle refinery gear drives

- Right-angle refinery gearbox repair

- Right-angle refinery gearboxes

- Single helical gearing

- Single-reduction cooling tower gearbox repair

- Single-reduction cooling tower gear drive repair

- Single-reduction cooling tower gear drives

JOIN HUNDREDS OF SATISFIED CUSTOMERS

EXPLORE PETROCHEMICAL RESOURCES

PROVEN SOLUTIONS FOR YOUR COMPLETE DRIVETRAIN SYSTEMPhiladelphia Gear operates at the core of critical applications, providing a complete range of custom-engineered products and services to keep operations running reliably.

-

1

Gearbox repair

-

2

New and replacement gearbox expertise

-

3

Gearbox replacement parts

-

4

Onsite technical services

-

5

Drivetrain solutions

1 Gearbox repair

Prevent unplanned downtime with advanced engineering and design processes backed by over a century of manufacturing expertise.

2 New and replacement gearbox expertise

Prevent unplanned downtime with advanced engineering and design processes backed by over a century of manufacturing expertise.

3 Gearbox replacement parts

Save time and eliminate worry knowing your parts are built to exacting OEM specifications, operating as well as, or better than, the originals.

4 Onsite technical services

Focus on your core business – our experts come to your location. Explore gearbox installation, repair, alignment, emergency services, and more.

5 Drivetrain solutions

As part of Timken Power Systems, we deliver a complete suite of electromechanical products and services from one trusted source.

Philadelphia Gear operates at the core of critical applications, providing a complete range of custom-engineered products and services to keep operations running reliably.

-

1Gearbox repair

-

2New and replacement gearbox expertise

-

3Gearbox replacement parts

-

4Onsite technical services

-

5Drivetrain solutions

1 Gearbox repair

Prevent unplanned downtime with advanced engineering and design processes backed by over a century of manufacturing expertise.

2 New and replacement gearbox expertise

Prevent unplanned downtime with advanced engineering and design processes backed by over a century of manufacturing expertise.

3 Gearbox replacement parts

Save time and eliminate worry knowing your parts are built to exacting OEM specifications, operating as well as, or better than, the originals.

4 Onsite technical services

Focus on your core business – our experts come to your location. Explore gearbox installation, repair, alignment, emergency services, and more.

5 Drivetrain solutions

As part of Timken Power Systems, we deliver a complete suite of electromechanical products and services from one trusted source.

KEEP YOUR MISSION-CRITICAL OPERATIONS MOVING. CONTACT OUR EXPERTS TODAY. We’re standing by to help with your most critical petrochemical challenges. Connect with one of our expert specialists today.

CONTACT US

We’re standing by to help with your most critical petrochemical challenges. Connect with one of our expert specialists today.